Elite Finishing Systems

It all started with one singular paint booth system that set the tone for our entire company and our commitment to high quality.

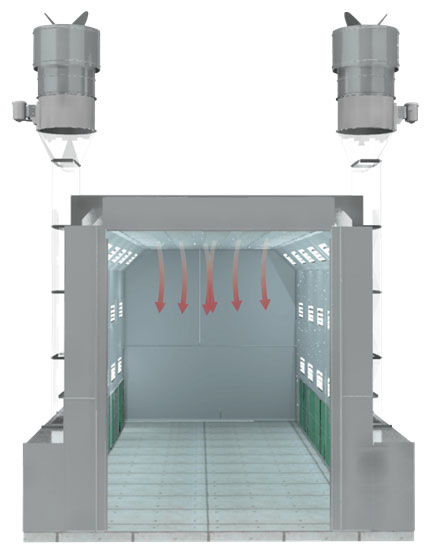

Modified Downdraft Airflow Designs

Airflow designs are a defining element of any spray booth, so it’s one of the first things finishing operators need to consider when upgrading to a new booth.

While there are only a handful of options when selecting a type of booth, each one carries a unique set of advantages and possible drawbacks. Airflow systems impact every aspect of a booth’s operation, so companies should carefully weigh how their chosen design will affect operating costs, quality of results and workplace safety.

Airflow designs are a defining element of any spray booth, so it’s one of the first things finishing operators need to consider when upgrading to a new booth.

While there are only a handful of options when selecting a type of booth, each one carries a unique set of advantages and possible drawbacks. Airflow systems impact every aspect of a booth’s operation, so companies should carefully weigh how their chosen design will affect operating costs, quality of results and workplace safety.

Recommended for:

Large Equipment and Automotive + High-Quality Finishing Requirements

• Powerful Performance

• Minimal Installation Requirements

• Additional Maintenance and Upkeep

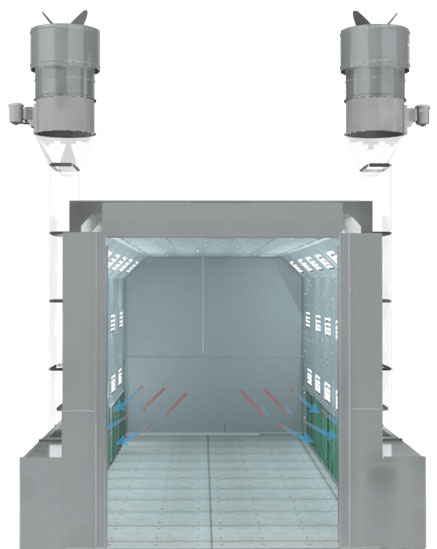

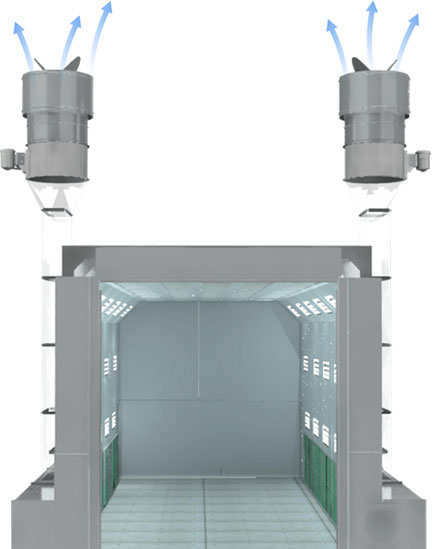

Modified downdraft airflow designs are similar to conventional downdraft systems, resulting in a powerful performance for higher-quality finishes. Compared to conventional downdraft booths, modified downdraft booths have the added benefit of not requiring a pit for installation. However, this means they require additional ductwork to operate efficiently which demands more intensive maintenance and upkeep. Sometimes referred to as a “side downdraft” booth, the term modified downdraft refers to how airflow travels towards the floor before being diverted to side exhaust plenums